Welcome To WAHSU World LLP

Or Call: (+91) 81780-01576

How IT WORKS?

Intumescent Paint

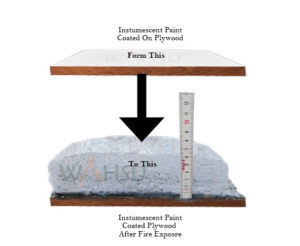

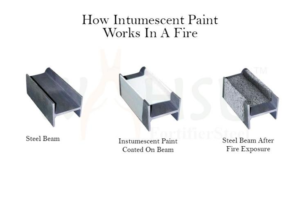

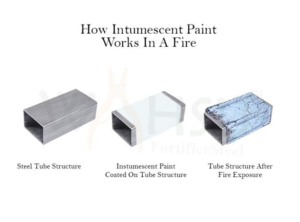

Intumescent paints are considered the lightest form of passive fire protection. An intumescent is a coating that, when exposed to heat, is rapidly transformed through sublimation, and expands many times its original thickness (up to 100 times), to form a stable, carbonaceous char. The resultant char reduces the conduction of heat from the fire to the substrate, delaying the time it takes to reach structural failure.

Intumescent paints are typically applied using airless spray paint equipment for speed and quality of finish. Depending on the project specification, usually up to 120 minutes, the vast majority of the Intumescent materials in the market would need several coatings to be applied in order to reach the required dry film thickness to protect the structure from failure.

Construction

Structural Fire Safety Standards

Fire resistance is not a property of a material but the performance of a complete element of structure which will generally be composed of a number of different materials and components. The fire resistance of load-bearing and non-loadbearing members, partitions and ceilings are determined by a test in accordance with the criteria of BS476: Parts 20- 22: 1987 & ASTM E119 respectively. Product supplied by WAHSU Insulation has been tested, assessed & certified by NABL for compliance with international standards. A fire resisting construction can be any one of a number of elements in a building for example a Steel column, beams, joist, deck sheet, wall, ceiling, duct, protected shaft or cavity barrier.

The following document gives details of some of the constructions used in fire resisting applications. For full details on many other fire resisting applications please refer download section. Non-combustible materials: Building materials are classified as noncombustible when they are tested to BS476: Part 4: 1970 or BS476: Part 11: 1982 – is non- combustible. These test provide a measure of the propensity of materials to generate heat and flames under standardize heat exposure conditions, and represent the highest and most stringent standard for the fire performance of materials.

Products

Our Products

FortfierSteel-Wx

FortfierSteel-Wx product is water-based intumescent coatings are generally more eco-friendly, and less-chemically smelling option. They produce less odour, however, these coatings are less tolerant to humidity and low temperatures and therefore may take longer to completely cure in such environments.

FortfierSteel-Ex

FortfierSteel-Ex product is solvent based coatings usually used in semi-exposed environments and are tested against weather and temperature variations. Solvent-based coatings tend to be more resistant to weather conditions as well as temperature changes and humidity. They also dry faster and have a smoother finish

FortfierSteel-Ex

FortfierSteel-Ex product is solvent based coatings usually used in semi-exposed environments and are tested against weather and temperature variations. Solvent-based coatings tend to be more resistant to weather conditions as well as temperature changes and humidity. They also dry faster and have a smoother finish

CPx

FortfierSteel-CPx

FortfierSteel-CPx product is epoxy-based intumescent is typically used in harsher environments such as the offshore marine industries or the chemical industry because these coatings provide excellent hydrocarbon fire protection. Epoxy-based intumescent comes in two-parts which when combined, forms a very thick and durable film that insulates the steel member and is highly resistant to corrosion

Gallery

Our Work

Get a Quote in Under 24 Hrs

Request an Online Quote

Or Call: (+91) 8178001576